If there’s one thing every mine site superintendent knows about haul truck tyres, it’s: “The more they turn, the more we earn.”

This notion is important because with each tyre costing at least R750k, the cost of replacing haul road tyres is one of the major expenditures in any mining operation.

With our haul road management services, it all comes down to where the rubber meets the road.

A good running surface is key to the life of haul truck tyres

If you are considering extending the life of your haul truck tyres, it all starts with running surface – the better the quality, the longer the tyre lifespan.

At Dust-A-Side, we’ve proven that a well bonded wearing course sealed with bitumen not only results in reduced loss of fines and less water ingress, but also leads to a less aggressive haul road surface from a tyre perspective.

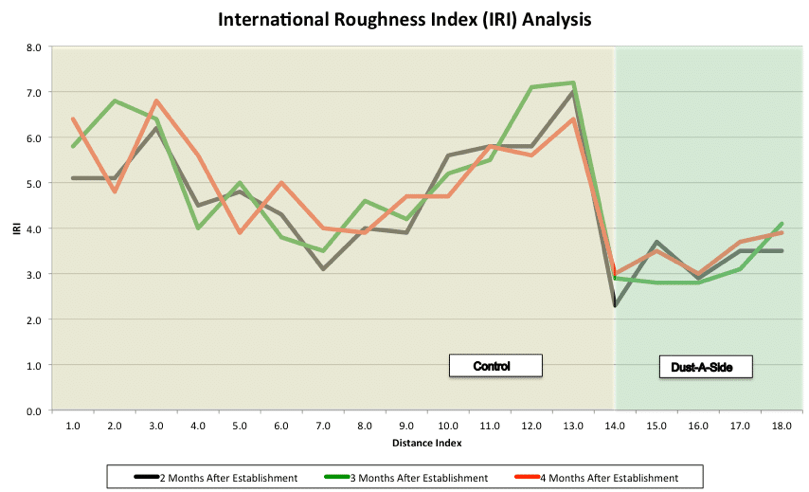

The International Roughness Index (IRI) is a worldwide standard for measuring road smoothness longitudinally (i.e. in direction of driving). The index measures haul road roughness in wheel path in terms of the number of metres per kilometre that a laser, mounted in a specialised vehicle jumps as it is driven along a road. The lower the IRI number at a given speed, the smoother the ride.

And as you can see from the following International Roughness Index (IRI) analysis, a Dust-A-Side established haul road resulted in a 37% reduction in IRI after just two months.

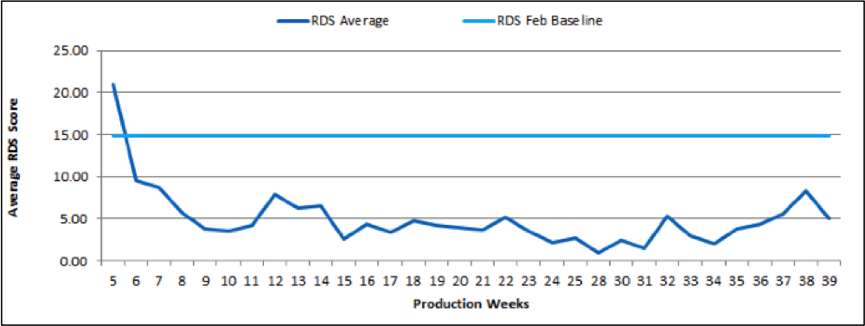

This improves haul truck tyres life significantly, and it is borne out by a low Roughness Defect Score (RDS).

Once again, in a study undertaken over a period of 32 weeks, a haul road treated with DAS Product proved to have a defect score around one-third of the average RDS on other comparable non-treated haul roads.

Less water on haul roads also improves tyre life

With the stabilised and sealed wearing course and on-going maintenance program, Dust-A-Side haul roads have a notably reduced need for water.

This is a vitally important point to remember because wet haul roads increase wheel slip, decrease traction and increase the cutting action of rocks – wet rubber is far softer than dry rubber and cuts 10 times more easily.

It has been proven that when water trucks are unavailable, the tyre rock damage is invariably lower.

Therefore, a reduction in water will:

- Decrease tyre wear rates

- Reduce the incidence of rock cuts, and

- Increase overall tyre life.

Reduced temperature – another factor affecting haul truck tyre wear and tear

It’s a scientific fact that the rougher a running surface is the hotter your tyres will run.

Tonne kilometre per hour (TKPH) measures the work load of a tyre, based on the weight and speed that the tyre can handle without overheating and causing it to prematurely deteriorate.

Theoretically when a tyre is operating at its TKPH rating, its internal belt temperature will be at its maximum. It is desirable that a radial tyre has an internal temperature of between 100 to 105ºC.

At 110 ºC, rubber reversion starts to occur and the tyre will be subjected to irreversible damage.

With this in mind, the tyre TKPH rating must always be greater than site operating TKPH; otherwise the strength of rubber is dramatically reduced.

Improve haul truck tyre performance, from the ground up

Rather than try to implement a “quick fix” on an existing haul road, it’s always best to design and build haul roads right the first time to improve tyre performance.

That way, everything can be taken into consideration, including:

- Haul road sub-base

- Camber

- Superelevation

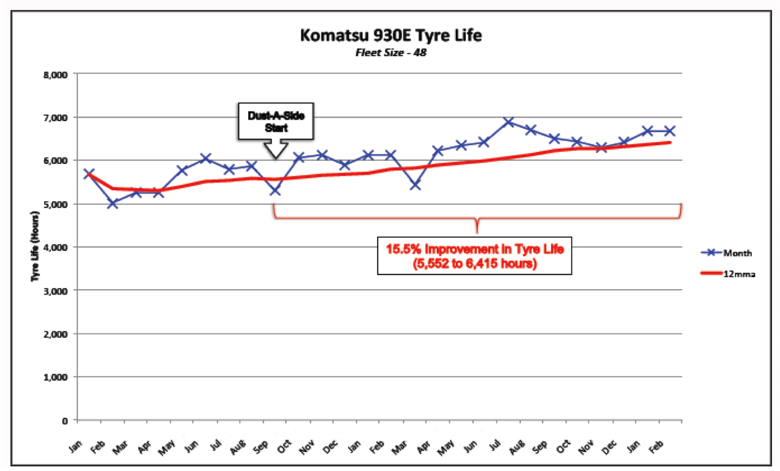

As you can see from this example comprising a fleet of 48 Komatsu 930E haul trucks, Dust-A-Side demonstrated a 15.5% improvement in tyre life over a 24-month period.

That was ON TOP of these extraordinary figures:

- Water savings of over 90%

- Fuel savings of over 5%

- Reduction in water cart fleet by up to 75%

- Grading reduced by up to 70%

- Electric motor life increased by up to 2.5 times

And that didn’t even take into account other potential gains such as:

- Strut & suspension life increased

- Improved braking and better brake life

- Road maintenance and need to rebuild reduced

- Less operator fatigue and injury

- 4WD not required

- Water proof layer and better drainage allowing more work during the wet and quicker restart after wet weather

- Increased life of equipment parts and consumables due to less dust

- Visual environmental improvement

What to learn more about haul road management?

For more information and advice about extending the life of haul road tyres with our haul road management services, please contact the expert team of engineers at Dust-A-Side on +27 12 648 8900 or simply click here to get in touch.

![DAS_South Africa-Logo_Y[P]_SA DAS_South Africa-Logo_Y[P]_SA](https://news.dustaside.com/hs-fs/hubfs/DAS-South%20Africa/SA%20Logo/DAS_South%20Africa-Logo_Y%5BP%5D_SA.png?width=670&height=175&name=DAS_South%20Africa-Logo_Y%5BP%5D_SA.png)