Upon speaking to various decision makers within the mining industry, Dust-A-Side has come to realise that there is some misunderstanding between the terms “dust prevention” and “dust suppression”.

We hear comments such as: “But aren’t they one and the same thing?” and “Can’t we just hose the material down and be done with it?"

In this article, we look at the differences between the two strategies, and explain why it is appropriate to use them for different purposes in different situations.

Wet dust control — a quick overview

As you will read in our free “Dust Suppression | Dust Prevention Comparison Sheet”, broadly speaking there are two types of wet dust control systems:

- Dust Prevention - Low pressure and high volume of water

- Dust Suppression - High pressure and low volume of water

As with most things, there are reasons for/against these two dust control strategies, depending on the situation and application.

In fact, many mining operations employ both systems in combination to produce the desired result.

Looking at dust prevention systems

Low pressure systems use large volumes of water to pre-wet the material and increase the moisture/humidity content. This is usually implemented close to the source such as the beginning of the transfer point so that during handling there should not be dust emitted.

However, while there is often a real need to soak material thoroughly with a low pressure system, there can be significant downsides for the site, including:

- Increased water usage (and its associated costs)

- Dealing with runoff all over the plant

- Excessive water pooling leading to health and safety risks

- Increased corrosion of conveyors and other infrastructure as water is carried through the entire plant

- Clogged up chutes, and

- Clogged up conveyors

Putting these problems aside, one has to think about the harmful dust that is not visible to the naked eye including airborne and ultra-fine dust.

This creates an opportunity for dust suppression systems.

Looking at dust suppression systems

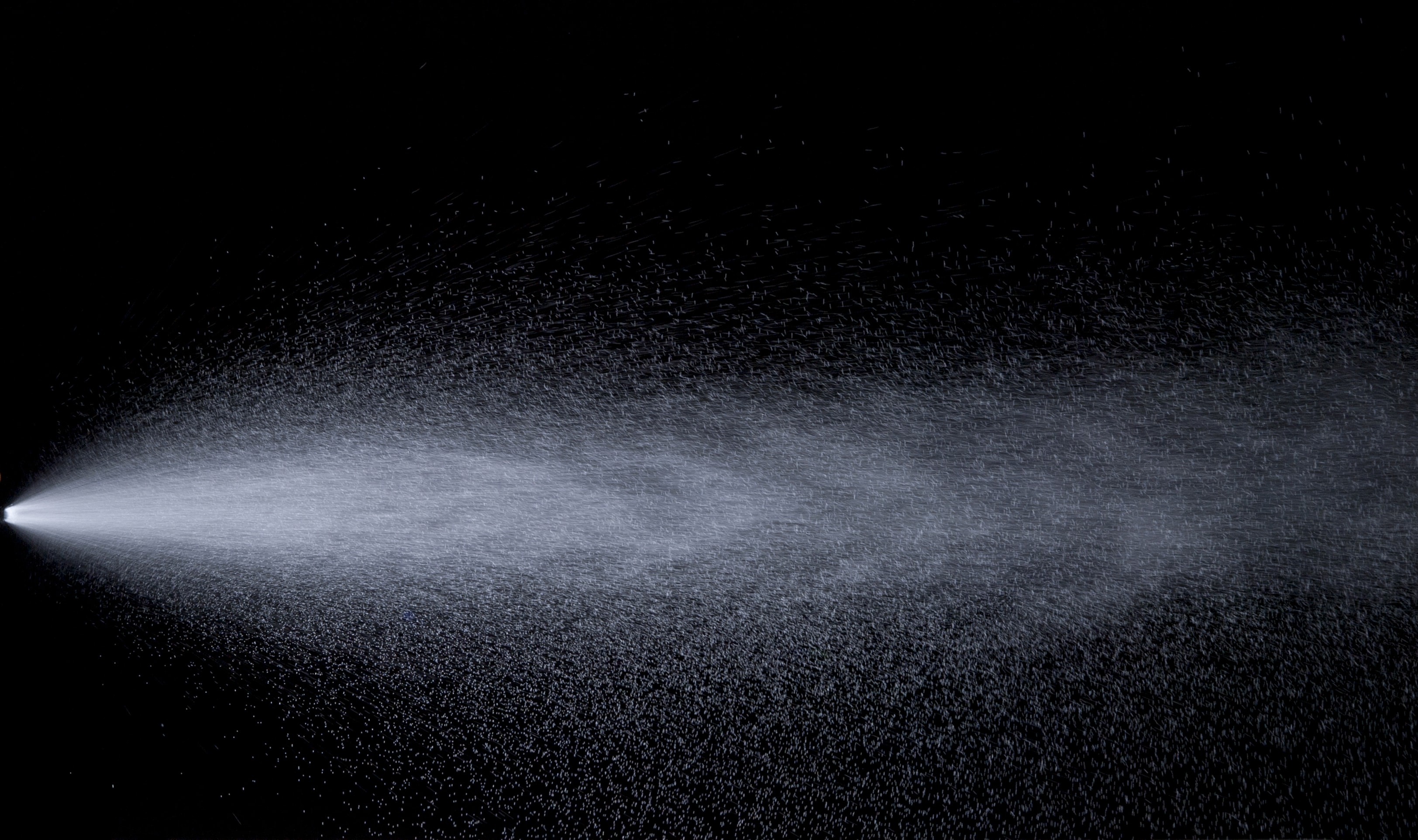

These systems use lower volumes of water at high pressure (more than 50 bar) to add a fine atomised mist to dust that is already airborne increasing the particle size causing it to settle due to gravity. this type of dust is more deadly as it lodges in the lower respiratory tract. Depending on the type of material handled, it can either clog or scar the lung tissues resulting in pneumoconiosis (i.e. black lung for coal and in some instances silicosis depending on the silica content available in the ore handled)

There are many other reasons why the high pressure dust suppression methodology is a preferred option for dust control, particularly when it is not possible or practical to pre-wet material.

One of the reasons is that the overall water usage is decreased, because moisture is added to the air when suppressing dust and not to the material itself.

This means that high pressure dust suppression systems have fewer short and long-term peripheral problems.

This type of dust control during material handling reduces the likelihood of blockages in the downstream materials handling processes caused by cloggy, wet material.

With dust suppression systems tailor made to suit their specific needs, clients can process and handle material at any point, confident that dust will not be a concern.

Dust suppression for coal and other fine ores

Some hydrophobic materials such as coal and other fine ores bring specific challenges. In these situations, the effectiveness of a high pressure dust suppression system can be enhanced by products such as Hydroplus, a concentrated surfactant specially formulated by Dust-A-Side to improve the wetting ability of water.

HydroPlus lowers the surface tension of water particles, which in turn enables the water particles to attract dust particles to them, through a process of agglomeration.

For effective dust suppression with coal and other fine ores, the selection of spray nozzles is another important issue.

For effective dust suppression, it is important that the water droplets are equivalent in size to the dust particles leading to smaller water droplets (between 5 and 10 microns); if the droplets are too large, the fast-moving airborne dust will simply flow around them.

The correct nozzles, when combined with HydroPlus will ensure that much higher levels of dust suppression can be achieved, with greatly reduced use of water on site.

High pressure dust suppression systems are ideal for the following plant and process areas:

- Tipping areas

- Conveyor transfer points

- Surge bins

- Crushers

- Screens

- Stockpiles

- Stacking and reclaiming

- Transfer chutes

- Train loud-outs

- Port terminals

- And more

Want to learn more about dust suppression systems for material handling?

A well designed and properly installed high pressure mist system is an economical long-term solution that, with regular maintenance, can provide years of trouble-free performance.

Dust-A-Side can help you get the performance you need for your specific environment and operating conditions

With over 200 fully operational dust suppression systems in use globally, from tip bins to load-out stations at the world’s largest mines, Dust-A-Side is an acknowledged leader in this field.

For more information and advice about our dust suppression systems, or to discuss anything to do with dust control, speak to one of our dedicated engineers today. Call +27 12 648 8900 or contact us.

![DAS_South Africa-Logo_Y[P]_SA DAS_South Africa-Logo_Y[P]_SA](https://news.dustaside.com/hs-fs/hubfs/DAS-South%20Africa/SA%20Logo/DAS_South%20Africa-Logo_Y%5BP%5D_SA.png?width=670&height=175&name=DAS_South%20Africa-Logo_Y%5BP%5D_SA.png)